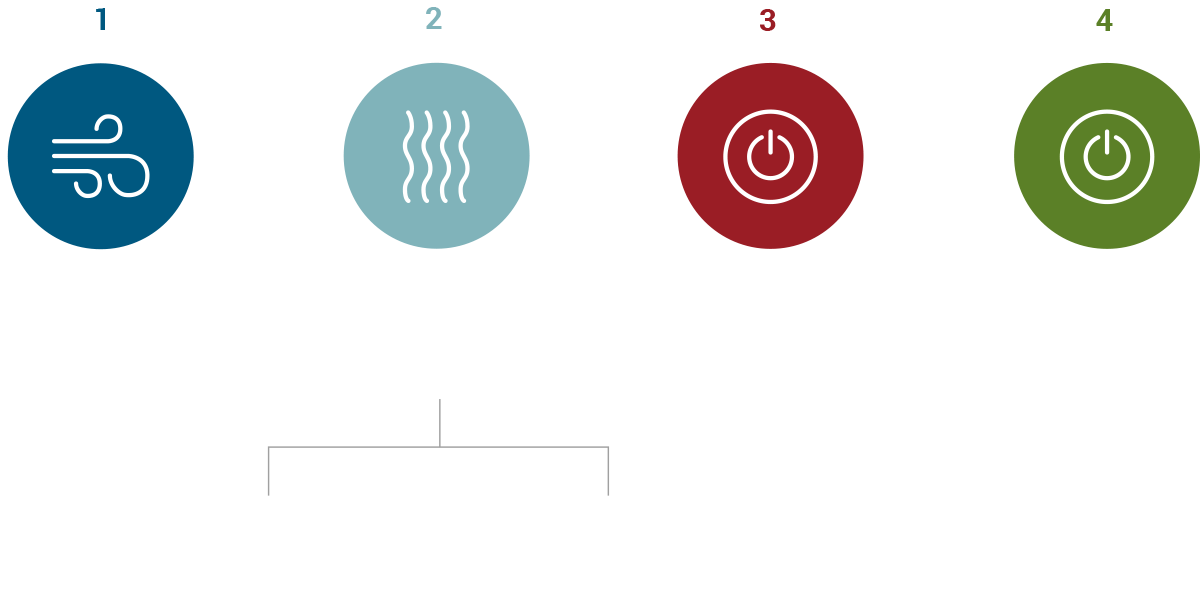

Available Systems

All our machines have this important function as a basic feature that allows both solids

and liquids to be vacuumed without the use of filters or bags that have to be replaced

every so often

1

Suction

Unhealthy air Unhealthy Air And Dust

2

First Filtering

Unhealthy air

3

Filtering with separator

A second filtering operation is then carried out by the exclusive “molecular separator” that manages to intercept and reject even the smallest particles.

The boiler is one of the main components of the machine, steam is created inside it.

Limescale is the boiler’s main enemy, Maxima uses technology designed to help reduce

the risk of clogging and malfunction.

1

Limescale removal injector for automatic refilling.

Automatic refilling

2

Stainless Steel

The body of our boilers is always made from stainless steel, for exceptional durability and to resist the pressure of the steam.

3

Resistance

One of the technologies applied to resistance consists of placing it inside an aluminum plate by means of the melting process. This plate is in turn fixed to the external bottom of the boiler and is never in contact with water.Thus excellent results are obtained against limescale and any resistance problems.

With 5 systems available, Maxima offers its customers a range of machines that can adapt to the most varied requirements: Plus, Automatic, Easy Plus, Easy and Basic are designed and built entirely in Italy with high quality components to last over time.

Technology

Air Suction and Cleaning , Steam Generation , Power jet enriched steam: , Cold washing .

Our new technology, designed to further improve the performance and reliability of our products.